- Home

- Page

Topographic Survey

We are known to provide an impeccable topographic survey to our clients. Through the help of our survey techniques, our clients can figure out the site that is suited best for petroleum drilling.

We offer best services to the client that may help to know the area and estimate their budget for further planning.

Ground Penetrating Radar

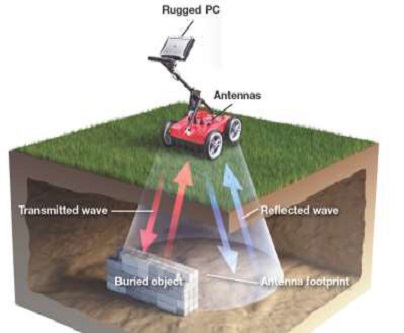

Ground Penetrating Radar (GPR) stands as a versatile geophysical technique extensively utilized across a wide array of applications and environmental conditions. It employs non-destructive, non-invasive methods, leveraging radar pulses to penetrate the subsurface and identify reflected signals from underground structures. A significant application of GPR is in locating underground utilities within the civil engineering and construction sectors.

Principles

Ground Penetrating Radar (GPR) utilizes brief pulses of high-frequency radio waves directed into the ground to gather information about the subsurface. When these waves encounter a buried object or a boundary characterized by a different dielectric constant, the receiving antenna records the variations in the reflected return signal.

Retro Energy’s team of experts provides the best services and effective results to the clients.

Groundwater Studies

The “Retro Energy” groundwater expertise team specializes in discovering, growing, observing, administering, and preserving our valuable groundwater resources.

We provide services in geology, hydrogeology, and geotechnical research. Our goal is to support and empower the informed, accountable, and sustainable use of groundwater while ensuring that environmental safeguards are optimized.

Expertise In:

We provide a range of sophisticated techniques for investigating groundwater and managing its resources.

Aquifer Studies

Hydrogeological Survey

Hydrological Investigation

Piezometric/Telemetric Installation

Gravity Survey

The Gravity Method is a geophysical prospecting technique that measures variations in the Earth’s gravitational field. These variations are a result of lateral changes in the density of rocks near the surface. The spacing between stations is determined based on the survey type, with a spacing range of generally 10 to 20 meters considered optimal for mineral exploration.

We provide genuine gravity survey to the client.

Applications

Hydrocarbon exploration

Fault studies

Identification of lithologies

Exploration of ore deposits

Detection of subsurface cavities

Exploration for mass estimation of mineral deposits

Large-scale geological structure studies

Magnetic Survey

Magnetic methods rely on measurements of minute variations at the Earth’s surface due to changes in the magnetic field. These variations occur as a result of the distribution of magnetized rocks.

While most sedimentary rocks are nearly non-magnetic, the rocks underlying them, such as igneous or basement formations, exhibit slight magnetic properties. Consequently, if geological movements occur in these areas, the resulting irregularities will manifest as corresponding changes in the intensity of the magnetic field at the Earth’s surface.

We provide genuine magnetic survey to the client.

Applications

Hydrocarbon exploration

Fault studies

Exploration of ore deposits

Exploration for mass estimation of mineral deposits

Large-scale geological structures

Engineering construction site investigation

Uphole Survey

The Uphole (UH) survey provides information about the near-surface velocities, depths, and thickness of the layers. that also provide the lithological information of the near subsurface at the point of drilling through cuttings. The first break amplitudes are also studied to identify the high-velocity medium.

Retro Energy’s team of experts provides the best services and effective results to the clients.

Limitations:

- Requirement of drilling resources like a drilling rig, water and water tanker etc.

- Requirement of considerable time for the drilling process.

- Uphole gives the near-surface information at the point of survey only and no information in lateral direction can be derived.

Seismic Refraction Survey

Seismic refraction (SR) or LVL is one of the most advanced geophysical techniques that profiles the subsurface by determining the path and velocity of compressional or shear waves. The recorded compressional waves are used to map geological conditions such as fractures, lithology, rock topography, gravel depth, sand and clay deposit determination, large boulder detection, water table depth, etc.

This method is widely used in civil engineering and environmental studies.

Retro Energy’s team of experts provides the best services and effective results to the clients.

Application

Geotechnical Surveys

Surface Wave Analysis

Detecting Shallow Faults and Fracture Zones

Mapping of Bedrock Topography

Engineering Geology

Mineral exploration

Site Remediation

Methodology

The geophones are laid out in a line and the signal is sent to the seismometer via a spreader cable. The receiver spread length should be 3-4 times the inspection depth. The source point location is not too close to the geophones and the source point offset is usually set on a trial basis for production work. Instead of a vertical offset, it is usually placed in a line slightly offset from the receiver line. This configuration allows the most accurate analysis of transition times as the shots are placed exactly at the ends of the line

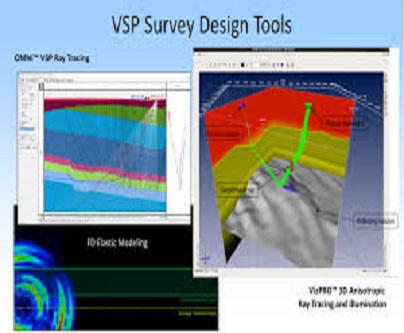

Vertical Seismic Profile (VSP)

VSP is a technique to map the Earth’s subsurface by gathering data from seismic events through ground-level triggers and placing receivers at various depths within a drilled hole.

Retro Energy’s team of experts provides services to the client for the best results to obtain rock properties (velocity, impedance, attenuation, anisotropy) in depth as well as seismic images of the subsurface.

Equipment and Energy Sources

(Uphole , Seismic Refraction & VSP )

Small Rig Manufacturing

We manufacture small rigs for the Shot hole drilling purpose. We usually manufacture mechanized rigs which will help you during the drilling process.

Our rigs are very cost economic plus they help to finish the drilling job within the allotted time frame. With the help of our rigs, you’ll also be able to save a considerable amount of money on manual labor which can be used for your organization’s core activities.

Our rigs are very safe and easy to operate plus they are known to produce less carbon emission and can be moved swiftly between two different drilling sites.

We also manufacture different parts of rigs viz. drill pipe, bit, elevator, desander, rotator table, etc.